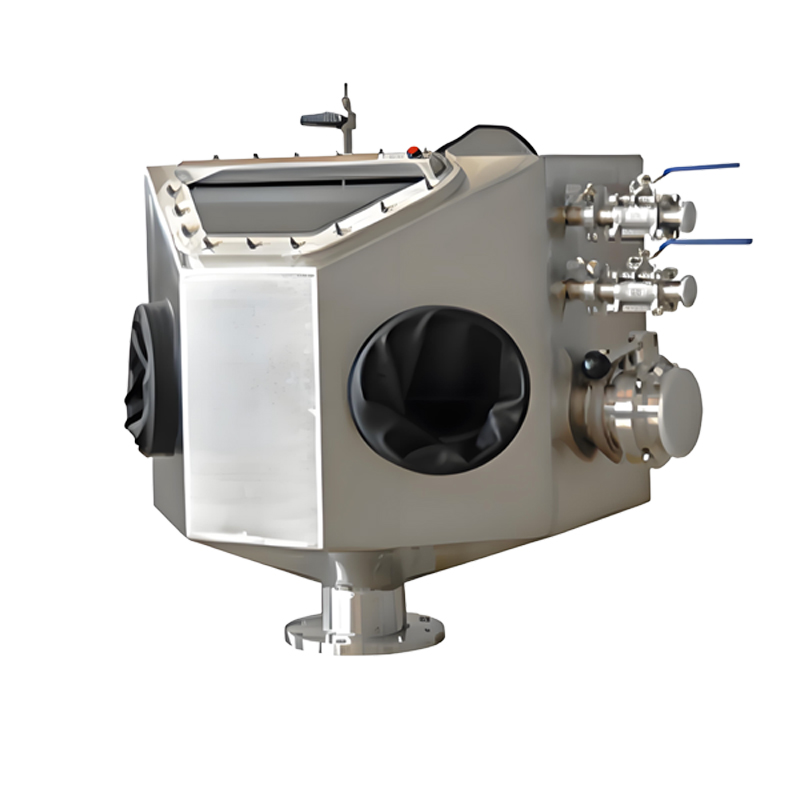

Products Description

Brief Introduction

Reactor Glove Box Charging System is designed for the safe and contained charging of powders, granules, or liquids directly into a reactor vessel. It provides an airtight barrier between the operator and the process, ensuring the highest level of protection.

Features

* Complete Containment: Creates a sealed transfer pathway, perfectly suited for handling toxic, potent (OEB 4/5), or moisture/oxygen-sensitive materials.

* Direct Reactor Integration: Eliminates exposure points during the charging process, protecting both the operator and the product integrity.

* Inert Atmosphere Capability: The closed loop can be purged with inert gas (e.g., Nitrogen) to maintain a controlled environment inside the reactor and glove box.

* Regulatory Compliance: Supports adherence to cGMP, FDA, and other stringent safety and quality standards in pharmaceutical and fine chemical industries.

Parameters

1. Dimensions: 800*600*600mm (customizable for non-standard requirements);

Operation Panel Material: Organic glass;

Chamber Material: 316 stainless steel;

Finely polished internal surface with Ra< 0.4μm;

Anti-detachment Fixing Device for Glove Interface

2. The bottom discharge port is connected to one DN100 PN16 flange.

3. The glove box adopts a quick-opening door on the left side, with door dimensions: 500*470mm.

4. The top of the glove box is provided with a φ100 sight glass, a DN40 sanitary quick-connect exhaust interface, a sanitary quick-install interface for cleaning solution inlet, a DN20 sanitary quick-connect interface for pressure gauge, and two fixed lifting hooks.

5. A DN40 nitrogen supplement interface is arranged on the upper right side of the glove box.

6. A DN200 PN10 flange bag-receiving interface is located on the lower right side, with a spacing of φ50mm from the box body.

Non-standard customization of feeding equipment is available according to user requirements.