Products Description

Brief Introduction

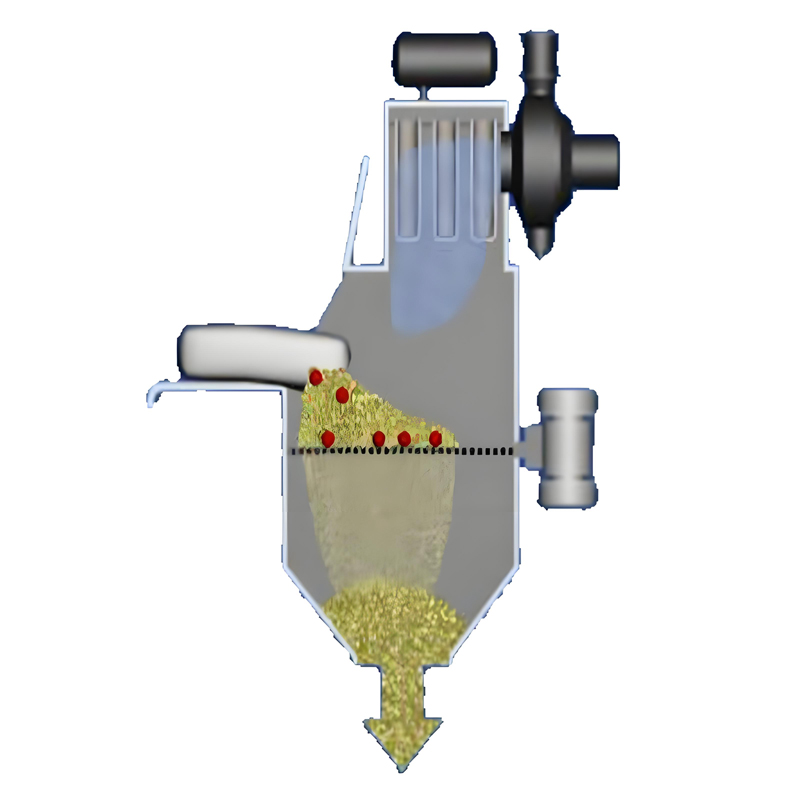

This fully enclosed unloading system is designed for the safe discharge of materials from boxes, bags, and drums into closed conveying systems. The operation involves manual bag/box opening and pouring steps to complete the unloading process. During discharge, any generated dust is automatically extracted and filtered by a dust collection unit mounted above the station, effectively protecting the working environment and the operator from contamination.

It is suitable for unloading powdered or granular materials from bulk or small bags in industries such as pharmaceuticals, food, chemicals, and batteries. It is particularly recommended for handling toxic and hazardous materials.

Features

*Safety: Features an integrated safety grating that is removable for maintenance.

*Simplicity: Modular design allows for flexible configuration based on material characteristics.

*Hygiene: Complies with GMP standards and meets CIP (Clean-in-Place) requirements.

*Quiet Operation: Generates low noise levels.

*Cleanliness: Ensures dust-free operation and is easy to clean.

Application Scenarioses

This system is designed for unloading powdered and granular materials from small bags (≥15 kg) in the pharmaceutical, food, and chemical industries. It is particularly suited for handling challenging materials, including those that are high-dust, toxic, hazardous, or allergenic.

Parameters

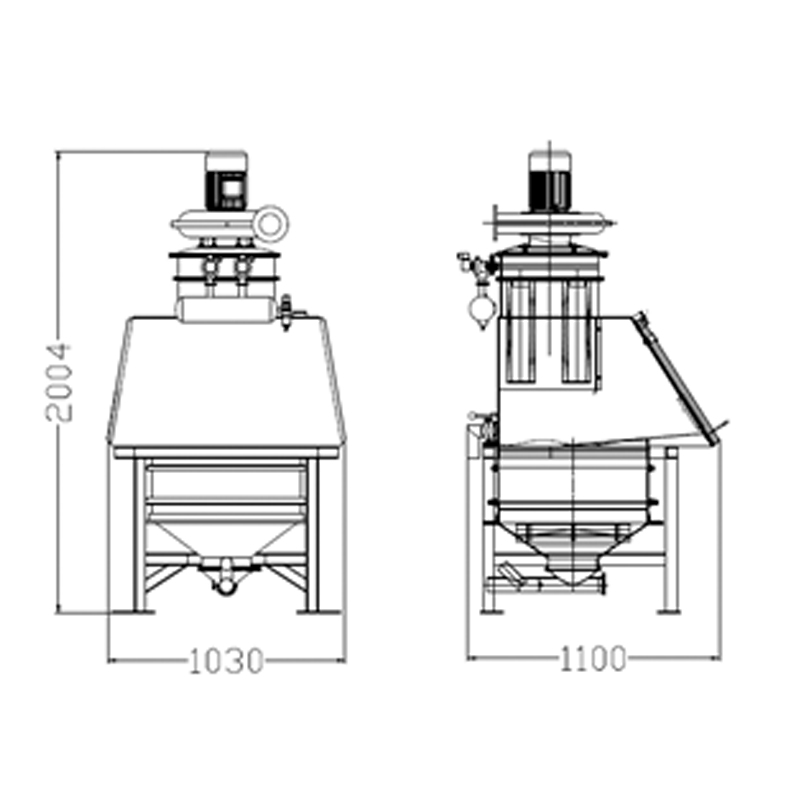

| Model | Capacity | Dust-removal Fan Power | Motor Power | Mesh count | Filter | Specification | |

| TLZ-1 | 800~4000L/h | 1.1KW | 0.07KW | As Custom | 0.5μm | L1030*W800*H2004mm | |

| TLZ-2 | 800~4000L/h | 1.5KW | 0.12KW | As Custom | 0.5μm | L1300*W1000*H2360mm | |

| Customizable | |||||||

| Model | Capacity | Dust-removal Fan Power | Vibration | Mesh count | Filter | Back - blowing Airbag | Specification |

| Motor Power | |||||||

| TL-800 | 800~4000L/h | 1.1KW | 0.15kw | As Custom | 0.5μm | 5L | L1000*W800*H2360mm |

| TL-1000 | 800~4000L/h | 1.1KW | / | As Custom | 0.5μm | 5L | L1300*W1000*H2360mm |