Products Description

Brief Introduction

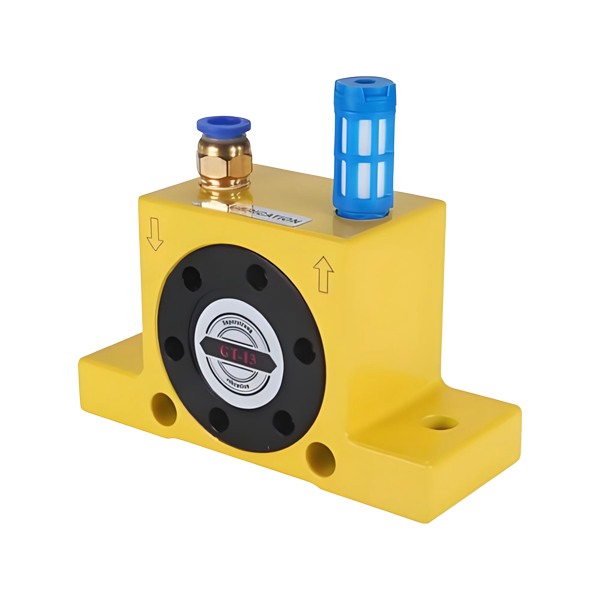

Pneumatic Turbine Vibrators are industrial-grade vibration devices that utilize compressed air to drive a rotating turbine, generating controlled mechanical vibrations. These robust tools convert pneumatic energy into high-frequency, low-amplitude vibrations through an ingeniously simple mechanism: compressed air propels turbine blades, creating rotational force that is transformed into precise vibrational output through an eccentric weight system.

The vibrators typically feature a durable aluminum or stainless steel housing, precision-balanced turbine components, and adjustable frequency controls. Available in various sizes and configurations, they deliver frequencies ranging from 2,000 to 18,000 RPM with variable force outputs, making them suitable for diverse material flow applications in hoppers, chutes, and silos.

Features

1. Exceptional Safety Performance

Explosion-proof operation without spark risk

No electrical components for hazardous environments

Cool operation prevents burn hazards

2. Superior Durability and Reliability

Minimal moving parts reduce failure points

Self-cleaning design resists contamination

Continuous operation capability

3. Energy Efficiency and Cost-Effectiveness

Low air consumption (typically 1-25 CFM)

Minimal maintenance requirements

Long service life with proper filtration

4. Precise Control and Versatility

Adjustable frequency and amplitude

Instant start/stop capability

Multiple mounting configurations

5. Environmental Compatibility

Oil-free operation options available

Low noise emission models

Suitable for food and pharmaceutical applications

Application Scenarioses

Food Processing: Gentle material dislodging in mixers, hoppers, and screens

Pharmaceutical Industry: Powder flow enhancement in processing equipment

Chemical Industry: Reliable operation in explosive atmospheres

Plastics Industry: Resin and pellet flow assistance

Mining and Minerals: Heavy-duty material movement in harsh conditions