Products Description

Brief Introduction

For vacuum vessels such as 2D mixers, 3D mixers, V-type mixers, double-cone mixers, and closed silos, vacuum feeders for mixers can be selected.

Through gas-solid separation devices like a three-way feeding valve, vacuum is drawn from the material-receiving equipment. Driven by the vacuum inside the material-receiving equipment, materials are directly sucked into the equipment through the feeding port.

In this feeding mode, materials remain in a continuous flow state, ensuring stable and fast feeding with a low failure rate.

Features

Designed and manufactured in strict compliance with GMP standards

Adopts airtight airflow design to prevent dust leakage, featuring a compact size, easy installation, and easy disassembly for cleaning

The inner wall undergoes precision polishing to prevent material adhesion

Equipped with intelligent control, enabling high automation and simple operation

The flap door feeding method is applied to non-sealed equipment (e.g., packaging machines, tablet presses, etc.)

The three-way feeding method is applied to sealed containers (e.g., 2D mixers, 3D mixers, V-type mixers, etc.)

Parameters

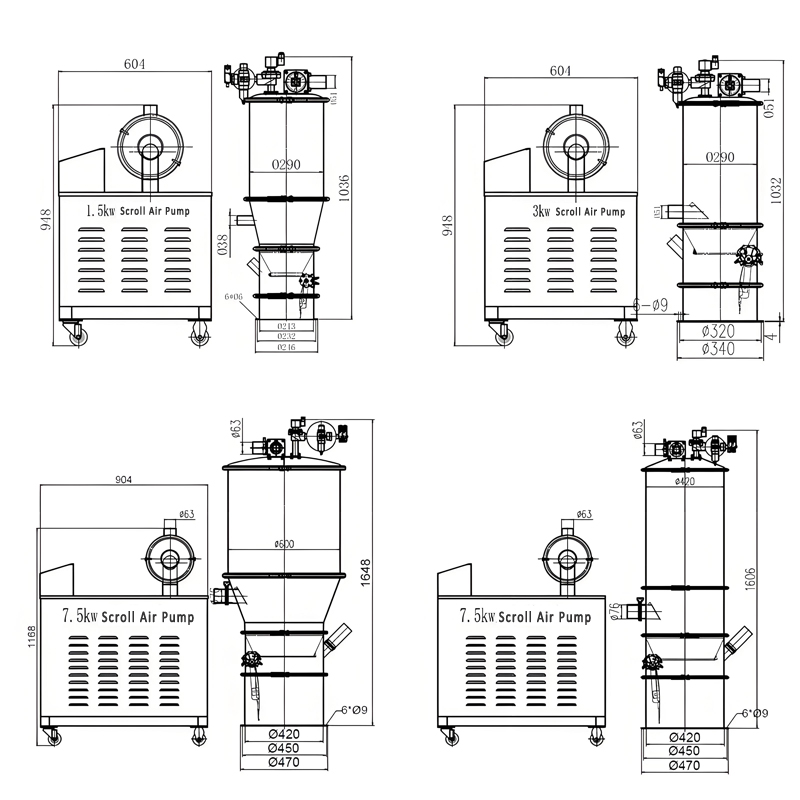

Model | Motor Power | Transport Capacity | Suction Port | Working Pressure | Gas Consumption | Size |

ZKS-1 | 1.5KW | 400kg/h | φ38mm | 0.4-0.6Mpa | 500NL/min | φ290*802mm |

ZKS-2 | 2.2KW | 600kg/h | φ39mm | 0.4-0.6Mpa | 500NL/min | φ290*802mm |

ZKS-3 | 3KW | 1200kg/h | φ51mm | 0.4-0.6Mpa | 500NL/min | φ290*952mm |

ZKS-4 | 5.5KW | 2500kg/h | φ51mm | 0.4-0.6Mpa | 500NL/min | φ420*1216mm |

ZKS-6 | 5.5KW | 3200kg/h | φ51mm | 0.4-0.6Mpa | 500NL/min | φ420*1216mm |

ZKS-7 | 7.5KW | 6000kg/h | φ63mm | 0.4-0.6Mpa | 500NL/min | φ420*1379mm |

ZKS-10-6 | 7.5KW | 6000kg/h | φ76mm | 0.4-0.6Mpa | 500NL/min | φ600*1907mm |

ZKS-20-5 | 11KW | 5000kg/h | φ102mm | 0.4-0.6Mpa | 500NL/min | φ800*2070mm |

Note: For detailed parameters, please contact us. Equipment selection can be made based on your requirements. | ||||||